sizcache="" sizset="47">

Paper has come to be an very important portion of our everyday lives, it is deemed as 1 of the standard necessities of man, practically every thing that we do involves the use of paper from doing office and school function to cleaning up ourselves. Yet some of us by no means realized how important paper is as we grow use to its abundance and availability, imagine how life would be without having paper, do you feel it will be the exact same? As paper plays a important role in our day-to-day lives it is very best to know how it is created so that we will have a glimpse of how it is produced in significant quantities to accommodate all its demand and wants.

In ancient times paper was created making use of the papyrus plant by shredding its fiber and beating it up to fine bits to get the material that is utilised to create paper. As time progressed the means of producing paper has evolved as well producing it doable for us to mass generate paper which in turn help revolutionized our way of life.

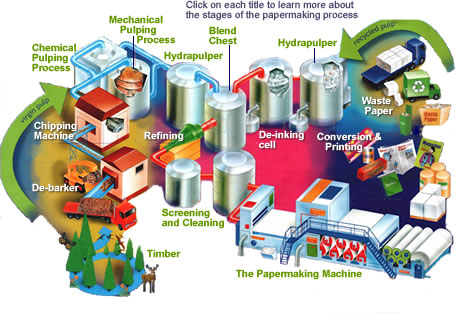

Here are some examples of the processes used in producing paper:

Chemical pulping:

Paper that is made from chemical pulping is identified as wood-totally free papers, this process breaks down the chemical structure of lignin to make it soluble in the cooking liquor for the primary of purpose of washing away its cellulose fibers. Lignin is a portion of the plant fiber that holds the plant cells together, chemical pulping is critical as it frees the fibers and makes pulp. Bleaching of the pulp can also be completed to generate white paper that is utilised for printing, painting, and writing. Chemical pulping tends to generate stronger paper compared to other processes as it preserves fiber length, nonetheless chemical pulps price greater because of its low yield, 40-50% of the original wood. This sort of papers is also identified as wood-free papers.

The Kraft procedure is an example of chemical pulping procedure that is commonly practiced these days. It produces strong and unbleached papers that can be utilized directly for bags and boxes but are quite often processed again to make corrugated cardboards.

Mechanical pulping:

In mechanical pulping the lignin of the fiber is not removed producing its yield extremely high and causes paper made from this pulp to yellow and come to be brittle over time. Mechanical pulps have rather short fiber lengths for this reason producing a weaker paper compared to those made from the chemical pulping process. Two key types of mechanical pulps are widely utilised right now, that would be thermo mechanical pulp (TMP) and groundwood pulp (GW). With the TMP method the wood is fed into large steam-heated refiners after it has been chipped then it is squeezed and fiberized among two steel discs. Groundwood approach on the other hand utilizes debarked logs which are fed into grinders where they are pressed against rotating stones and have its fibers no cost and then created to a pulp.

Recycling:

This type of process can use either mechanical or chemical pulp exactly where hydrogen bonds in the paper are broken to separate the fibers once again with the use of water and applying mechanical action into the paper. These sorts of paper is also identified as deinked pulp and fundamentally has the very same quality or lower than the collected paper it was produced from, consequently most recycled papers contain only a portion of virgin fiber in terms of good quality.

Tidak ada komentar:

Posting Komentar